Versatile Applications and Cultivation Insights of Hemp hurd.

Hemp hurd, also known as shives or core fiber, is a highly versatile material derived from the inner woody core of the hemp plant’s stalk. It has gained popularity as an eco-friendly and sustainable resource with various applications across industries. In this blog, we’ll explore how hemp hurd is produced, its different processed forms, the cultivation process, harvest time, water and nutrient requirements, soil pH, and its applications in textiles, plastics, construction, and more.

Production and Processed Forms of Hemp Hurd:

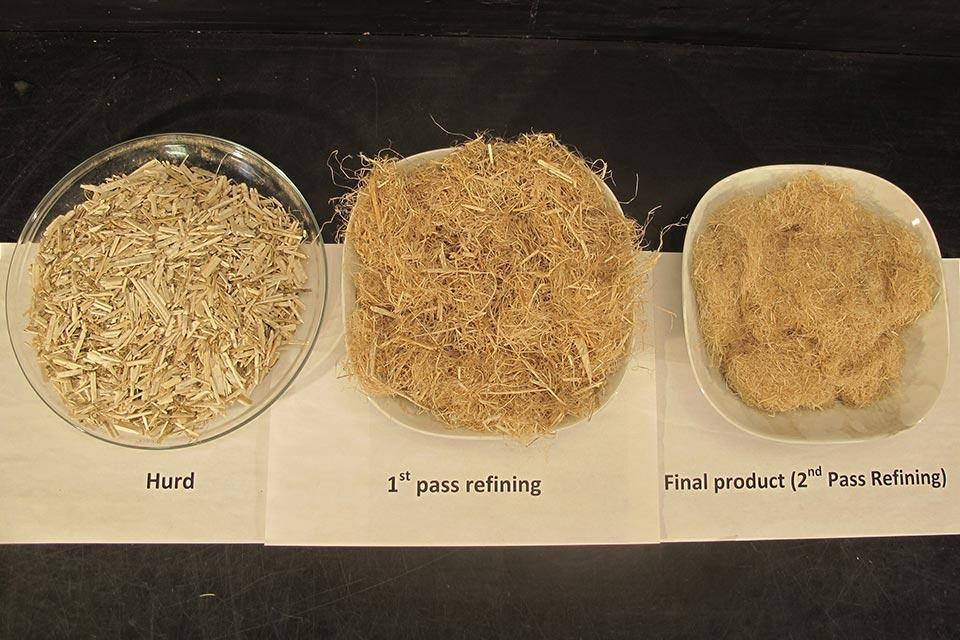

- Hemp hurd is obtained through a process called decortication, where the hemp stalks are mechanically crushed and separated into different components.

- These components include the outer bast fiber, the inner hurd or shives, and the core fiber.

Processed forms of hemp hurd are categorized based on their size:

- 3-5mm: Fine hemp hurd – This fine form of hemp hurd is ideal for applications that require a more uniform and lightweight material, such as animal bedding or as a component in insulation materials.

- Chips: Hemp hurd chips are small pieces of hurd that are used in animal bedding and other applications.

Pellets: Hemp hurd pellets are compressed pieces of hurd that are used in animal bedding and other applications.

- 6-12mm: Medium hemp hurd – Medium-sized hemp hurd strikes a balance between the fine and coarse forms, making it suitable for applications like composite materials or in creating eco-friendly bioplastics.

- 15-25mm: Coarse hemp hurd – Coarse hemp hurd is the largest fraction and finds its use in applications like hempcrete construction, where it is mixed with lime or cement to create a strong, lightweight, and insulating building material.

Cultivation Process:

- Optimal Seasonal and Climate Considerations:

- Hemp is a highly adaptable plant that can be cultivated in a variety of climates, but optimal growth and hurd production require specific conditions. Hemp thrives in temperate climates with well-defined seasons. The best time to plant hemp is in the spring when the soil has warmed to around 50-60°F (10-15°C). The growing season should be frost-free and have a minimum of 12 hours of sunlight per day.

- Length of Time for Harvest:

- Hemp is a fast-growing crop, and the time to harvest depends on the hemp variety and the purpose of cultivation. Generally, industrial hemp for fiber and hurd production is harvested at around 70-90 days after planting when the plants reach their peak biomass and before flowering.

- Water Quantity per Plant per Day during the Entire Cycle:

- Hemp is known for its low water requirements compared to other crops like cotton. On average, a hemp plant needs about 20-30 inches of water during its entire growing season, which translates to approximately 0.25-0.35 inches (6-9 mm) of water per day. However, water needs may vary depending on factors such as climate, soil type, and plant growth stage. It is essential to monitor soil moisture levels and avoid overwatering, as it may lead to root rot and reduced fiber and hurd quality.

- Nutrients Required:

- Hemp is a heavy feeder and benefits from well-fertilized soil. The primary nutrients required are nitrogen, phosphorus, and potassium, but hemp also needs micronutrients like calcium, magnesium, and sulphur. Proper soil testing and balanced fertilization are essential to support healthy hemp growth and high-quality hurd development.

- Soil pH for Best Growing:

- Hemp thrives in a slightly acidic to neutral soil pH range of 6.0 to 7.5. This pH level allows for optimal nutrient uptake, which is crucial for healthy plant growth and hemp hurd development.

- Applications of Hemp Hurd:

Hemp hurd has a wide range of applications due to its unique properties and sustainability.

Some of the key uses include:

- Textiles: Hemp hurd can be processed into fiber to create textiles with excellent breathability and durability. Hemp clothing is known for its eco-friendly and hypoallergenic qualities.

- Yarn, Rope, and Twine: Coarse hurd is suitable for creating strong yarn, ropes, and twine used in various industries, including agriculture, construction, and shipping.

- Plastic: Hurd can be mixed with bioplastics to create a more sustainable alternative to traditional petroleum-based plastics.

- Construction: Hurd mixed with lime or cement creates a lightweight and insulating material called “hempcrete,” ideal for eco-friendly construction, also hemp insulation, and hemp fiberboard.

- Rebar and Wood Alternatives: Hurd can be pressed into boards, like plywood, for use in construction and as a wood substitute.

- Fiber and Hurd Products: Hurd can be used as an animal bedding material due to its absorbent properties, making it an eco-friendly alternative to traditional bedding materials, as well as comfortable and safe bedding for animals.

Retting and Fiber Stalk Diameter:

- Retting is a process used to separate the bast fiber from the hemp stalk. It involves natural decomposition of the pectin that binds the fiber to the hurd. There are two main types of retting: dew retting (exposing hemp stalks to the elements) and water retting (submerging stalks in water).

- Water retting: In water retting, the hemp stalks are submerged in water for several weeks. The water breaks down the pectins in the stalks, and the fibers are separated.

- Dew retting: In dew retting, the hemp stalks are laid out in a field and allowed to rett in the dew. The dew breaks down the pectins in the stalks, and the fibers are separated.

Once the hemp stalks have been retted, they are dried and the fibers are separated from the hurd. The hurd is then processed into various forms, depending on its intended use.

- The ideal diameter of the fiber stalks for retting varies depending on the intended use. For textiles, finer fibers are preferred, typically around 3-5mm. Coarser fibers in the range of 15-25mm are more suitable for applications like construction materials.

Best Hemp Strains for Different Applications:

The best seeds for each product type will depend on the specific requirements of the product. For example, some seeds are better suited for making textiles, while others are better suited for making construction materials. However, in general, the best seeds for hurd and hemp stalks are those that are high in fiber content. Different hemp strains may have varying characteristics that make them more suitable for specific products

- Futura 75: Futura 75 is a high-yielding variety that is known for its long, strong fibers. It is a good choice for making textiles and construction materials. Futura 75 is a European variety that is well-suited for temperate climates. It has a long growing season, typically taking 10-12 weeks to flower.

- Futura 83: Futura 83 is another high-yielding variety that is known for its long, strong fibers. It is a good choice for making textiles and construction materials. Futura 83 is a European variety that is well-suited for warm climates. It has a long growing season, typically taking 10-12 weeks to flower.

- Yuma: Yuma hemp is a high-fiber variety that is well-suited for making hurd and stalks. It is a good choice for animal bedding and other applications. Yuma is a North American variety that is well-suited for warm climates. It has a shorter growing season than Futura 75 or Futura 83, typically taking 8-10 weeks to flower.

All these varieties are high-fiber and well-suited for making hurd and stalks. They are all relatively easy to grow and require regular watering. The best variety for you will depend on your specific needs and growing conditions.

Some other popular varieties of hemp seeds for hurd and stalks include:

Polish hemp: Polish hemp is a high-yielding variety that is known for its long, strong fibers. It is a good choice for making textiles and construction materials.

Chinese hemp: Chinese hemp is another high-yielding variety that is known for its long, strong fibers. It is a good choice for making textiles and construction materials.

Conclusion:

Hemp hurd is a remarkable material with a multitude of applications and a positive environmental impact. Understanding the cultivation process, including water and nutrient requirements, as well as retting techniques and stalk diameter for various uses, is crucial for maximizing the potential of this versatile resource. As more research and innovations occur in the hemp industry, the potential for hemp hurd to replace conventional materials and contribute to a more sustainable future continues to grow.

Disclaimer: Always consult with industry experts, such as THCV (The Hemp and Cannabis Vision), via email on info@thcv.co.za or through their website, www.thcv.co.za, and adhere to local regulations before engaging in hemp cultivation or using hemp-derived products.

Add a Comment